ANYWHERE

where hygiene is required, or when surface finishing needs to meet aesthetic challenges, corrosion-resistant, colour-fast and scratch-proof enamel is used.

Wendel direct quote

„Our rotary furnaces fuse the enamels without leaving any residue. The melted mass is absolutely free of bubbles thus producing the perfect Wendel frit with the best possible processing properties: perfectly smooth and 100% in perfect condition“, says Eckhard Voß, R&D Director.

Variety

in industry, agriculture, household, arts and design – fields of application, application processes, product types and substrates

-

Fields of application

-

Application processes

- Wet application

- Manual spraying

- Robot gun spraying

- Dipping

- Flooding

- Vacuum application

- Application in the electric field

-

Product types

- Individual components

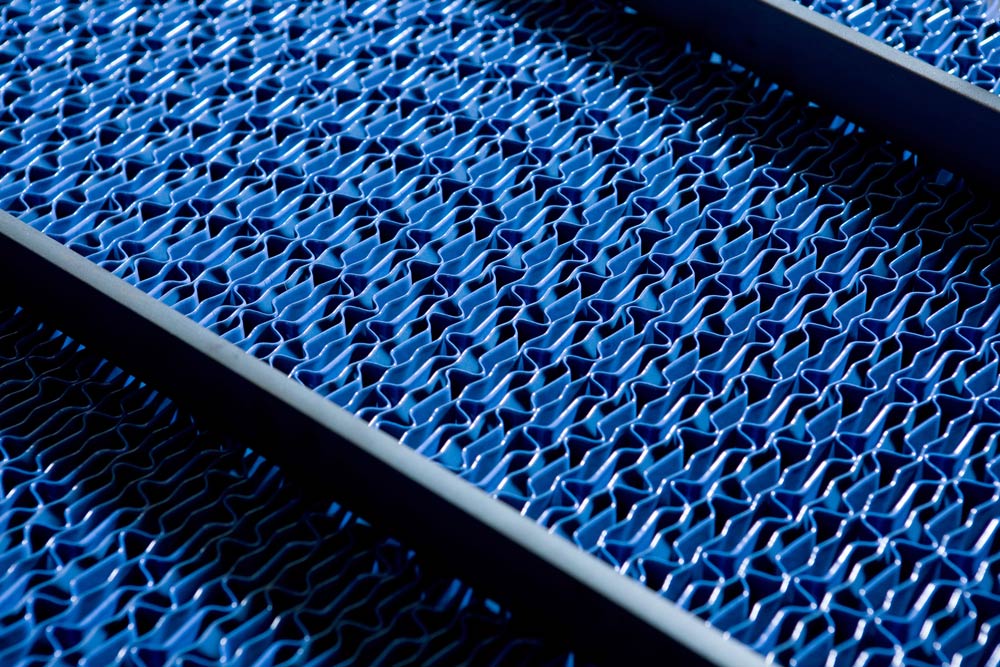

- Frits in the form of flakes or granules, milled, in the form of mottles and also in grain fraction sizes

- Additives

- Colouring oxides

- RTM (Ready-to-mill)

- Ready-to-mill mixture

- Already perfectly weighted and mixed

- RTU (Ready-to-use)

- Ready milled

- Can be used immediately – just add water

-

Substrates

Sheet steel

The all-rounder

Sheet steel is the most common enamel substrate. It can be enamelled using thicknesses of 0.4 to more than 16 millimetres. Different types of steel require different methods such as conventional or direct-on white enamelling. DC01EK and DC04EK steels are available for conventional enamelling. DC06EK and DC06ED are used when special deep drawing properties are required. Direct-on white enamelling uses zero-carbon qualities DC03ED and DC04ED. The most important requirement is to meet quality standards and specifications during manufacture.

Cast iron

The classic substrate

Enamelling transforms cast iron products into truly versatile all-rounders: stoves, bathtubs, fire hydrants and pots, to name but a few fields of application. Different casting processes are available to achieve the best possible specific product properties: grey cast iron is suitable for constructions where vibrations need to be dampened and there is little tensile stress. Spheroidal graphite iron casting makes cast iron ductile and malleable, the material achieves high strength. Chill casting produces cast iron with high resistance. During malleable iron casting, the material is subjected to heat treatment for several days. This produces a cast iron that is suitable for machining and welding and has similar properties to grey cast iron.

Aluminium

The lightweight material

Aluminium is light and easy to mould. When combined with an enamel surface there are no limits to decorative and aesthetical designs: easy-to-use and corrosion-resistant – Wendel enamels can be used for very thin coat thicknesses and are available in a wide range of colours. The enamel is fired-on in the low temperature range between 500°C and 600°C, thus saving energy. The vitreous coating protects cooking grates and plates in barbecues or iron griddles. Architectural and artistic creations are also being increasingly used outdoors.

Stainless steel

A success story

Enamelling of stainless steel is gaining in popularity. Besides surface protection, the insulating effect of enamel in heating technology plays an increasingly important role: heat transfer in heating systems with enamel-coated heating elements is considerably higher, heated liquids are available as soon as the household appliance is switched on without being pre-heated, and hotplates warm up immediately and do not overheat. Leakage current can be measured using dielectric enamels and used as control elements – application possibilities for high-quality enamelled stainless steels in innovative heating technology and building services solutions are constantly increasing. Ferritic stainless steels of grades 1.4016, 1.4512 and 1.4521 as well as austenitic types of grades 1.4301, 1.4307 and 1.4401 are suitable for enamelling.

Copper, silver, gold, platinum

Exotic materials

Copper, silver, gold and even platinum can be decorated with enamel. When enamelling jewellery, there is a particular demand for substrates like copper and the precious metals silver and gold. Rings, necklaces, bracelets or medals are created using coloured enamel powders. Platinum is a heavy, malleable and ductile transition metal. It is highly resistant to corrosion and also a very popular substrate for use with decorative enamel applications.