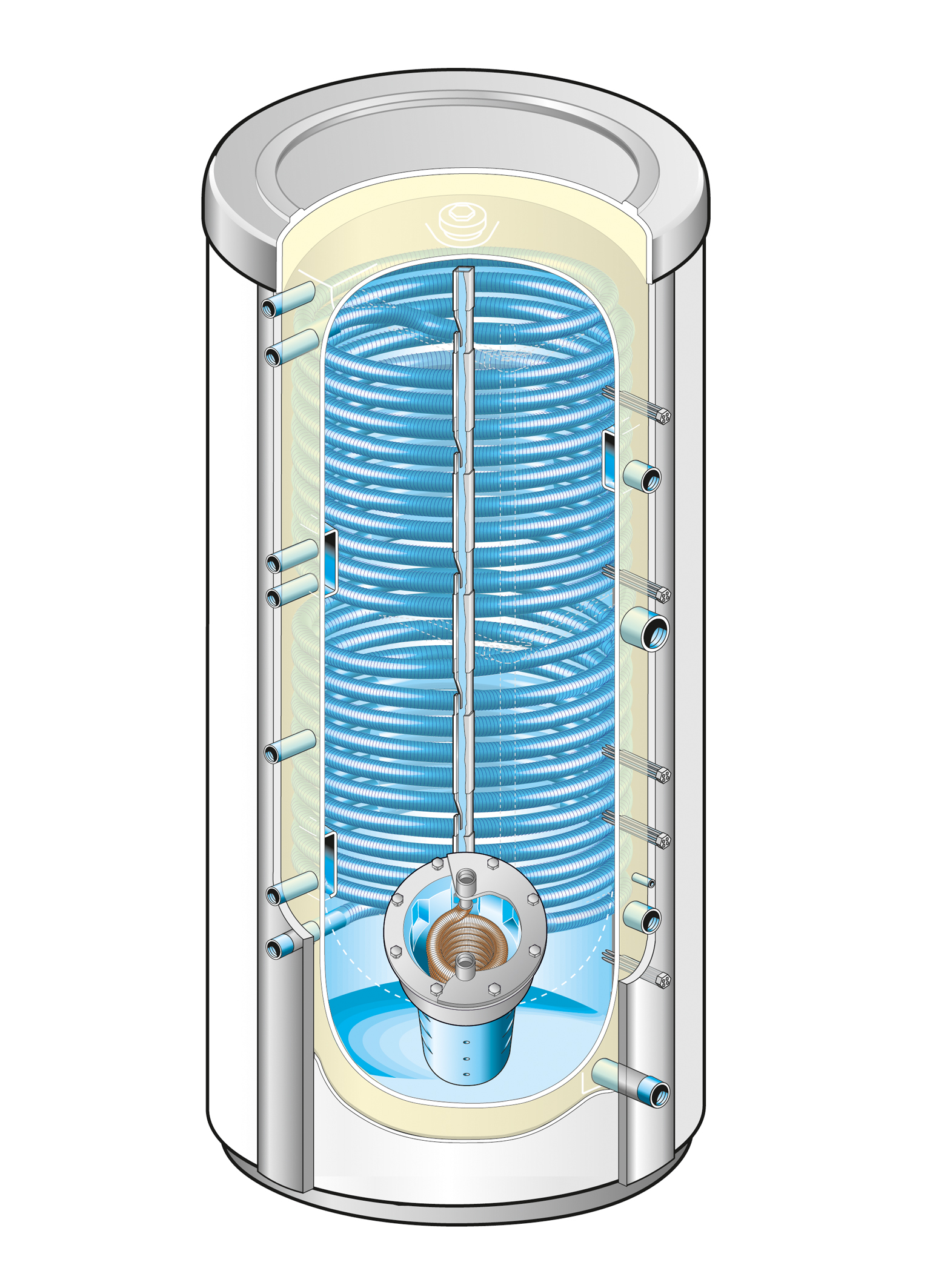

Enamel for hot water tanks: because it makes sense

FOR MORE THAN 40 YEARS

almost every manufacturer in the branch has relied exclusively on enamelled hot water tanks. Depending on its quality or condition, hot water is a comparatively aggressive medium and can cause corrosion on the inside walls of tanks. Enamel offers the most reliable protection. In addition, enamel always remains electrically neutral allowing the tanks to be connected without problem to any water supply. High-quality Wendel enamels have proved extremely resistant to hot water and will continue to do so in the future. Because it makes sense.© Buderus

© Buderus

© Buderus

Abb.: Max Weishaupt GmbH